Flow meter – unassuming yet indispensable devices that silently orchestrate the symphony of fluid dynamics across a multitude of industries. From the surge of oil in pipelines to the graceful glide of water in treatment plants, flow meters are the unsung heroes that ensure the harmonious flow of liquids and gases. In this exploration of the world of flow meter, we will traverse the landscape of their types, dive into their applications, and unravel the intricate tapestry of their importance in maintaining operational excellence.

Unlocking the Essence: The Flow Meter’s Purpose and Operation

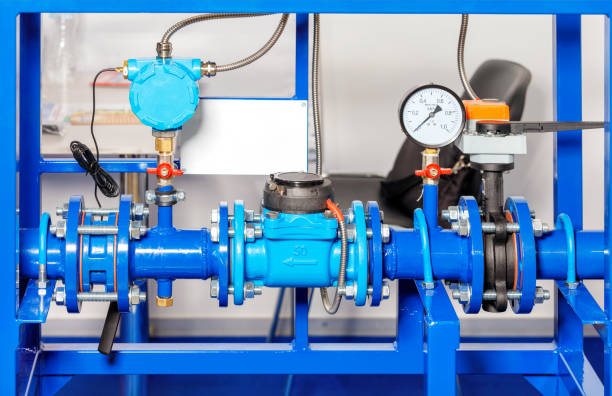

A flow meter is no mere tool; it is the sentinel that stands vigilant at the crossroads of fluid movement. Its primary role is to quantify the rate of flow – a feat achieved through various ingenious mechanisms. At its heart, the flow meter embodies accuracy, reliability, and control.

The Symphony of Variety: Types of Flow Meters

- Differential Pressure Flow Meters: Imagine a bottleneck on a highway; the pressure difference across it mirrors the flow rate. This concept lies at the heart of differential pressure flow meters. Orifice plates, Venturi tubes, and flow nozzles are the trailblazers here. Orifice plates are like gatekeepers, providing cost-effective measurements. Venturi tubes, the versatile performers, guarantee precision. Flow nozzles, akin to steadfast sentinels, shine in challenging conditions.

- Velocity Flow Meters: These meters embrace fluid velocity as their guiding star. Electromagnetic, ultrasonic, and vortex shedding flow meters populate this realm. Electromagnetic meters wield Faraday’s law for conductivity-based fluids. Ultrasonic meters, like whispers in the fluid, use reflections to unveil flow rates. Vortex shedding meters, with their dance of vortices, offer reliable readings in diverse settings.

- Positive Displacement Flow Meters: These meters measure by capturing the fluid in a chamber. Imagine it as a cycle of filling and emptying a cup. Rotary, reciprocating, and nutating disk meters are the custodians of this technique. Accuracy is their forte, making them pivotal for tracking even the most viscous fluids.

- Mass Flow Meters: These meters dance to the rhythm of mass, not volume. Thermal and Coriolis flow meters lead this graceful parade. Thermal meters measure heat transfer, while Coriolis meters engage the Coriolis effect for an intricate ballet of mass measurement. They shine in precision-demanding industries like chemicals and pharmaceuticals.

- Open Channel Flow Meters: Picture a river’s flow – open, exposed, and dynamic. Open channel flow meters tame this wild elegance. Flumes, weirs, and ultrasonic sensors become its gentle companions, ensuring the accuracy of the journey.

Applications: Where Flow Meters Paint Precision

Flow meters don’t just quantify; they optimize. In the grand tapestry of industries, their threads are woven intricately:

- Oil and Gas: In pipelines that traverse continents, flow meters safeguard efficient transportation.

- Water Treatment: Flow meters choreograph the purification of water, aligning efficiency and conservation.

- Pharmaceuticals: The dance of fluids in pharmaceutical processes is guided by the rhythm of flow meters, ensuring the highest quality products.

- Food and Beverage: Beverages flow seamlessly from factories to cups, with flow meters ensuring the right blend.

- Chemical Manufacturing: In laboratories and factories, flow meters orchestrate chemical reactions with impeccable precision.

Harmony in Measurement: The Importance of Accuracy

Accuracy – the cornerstone of flow measurement. Inaccuracies ripple across industries, impacting efficiency, product quality, safety, and regulatory compliance. Flow meters stand as guardians against these ripples, ensuring smooth operations and minimizing disruptions.

The Maestro’s Baton: Factors Influencing Flow Meter Selection

Choosing the right flow meter is akin to selecting a conductor for an orchestra. Fluid properties, flow rate range, pressure, temperature – these notes harmonize to determine the perfect meter. Installation and maintenance requirements further define the conductor’s style, ensuring that the symphony remains uninterrupted.

Precision’s Orchestra: Installation, Calibration, and Maintenance

Installation isn’t just placement; it’s the prologue to precision. Calibration elevates the meter to its true potential, ensuring every note is pitch-perfect. Regular maintenance keeps the symphony alive, sustaining accurate readings throughout the performance.

Troubleshooters and Innovators: Navigating Challenges and Advancements

From minor hiccups to major crescendos, troubleshooting is an art. Understanding common issues and their resolutions ensures the symphony’s continuance. Yet, innovation is the secret ingredient, transforming flow meters into technologically advanced virtuosos. Digital interfaces, wireless connectivity, and IoT integration revolutionize the way we perceive and interact with these devices.

The Grand Finale: A Symphony of Wisdom

In the finale of our exploration, the overture of knowledge resonates. Flow meters – these unassuming yet resolute instruments – empower industries, shaping their melodies of efficiency, quality, and precision. As we embrace the symphony of flow meters, let’s remember that each measure is more than a unit; it’s a testament to human ingenuity, orchestrating the symphony of fluid dynamics with unparalleled grace.